Connection Element: Gayrettepe – New Airport Metro Line

In the second article of our journey, we will take a closer look at some details of the Gayrettepe Metro station, which are difficult to associate and create complex repetitions, with an interdisciplinary perspective.

While the challenges of working underground stem from the nature of metro construction sites, the fact that the mentioned Gayrettepe Metro Station is the most integrated station in Istanbul complicates the problems even more. One of the most important issues to be mentioned in such areas is the connections where the opened tunnels intersect with each other. Moreover, the equation of tunnel-type intersections makes this connection a bit more challenging.

Reduction Belt as the Connection Element

The magical formula to eliminate this problem provides reduction points that connect the main and intermediate corridors. These points, called reduction belts, not only ensure the harmony of two volumes and the materials in these volumes but also indicate the internal circulation routes. These belts, used to simplify the functional requirements and technical challenges of the volume, consist of a series of elements and details.

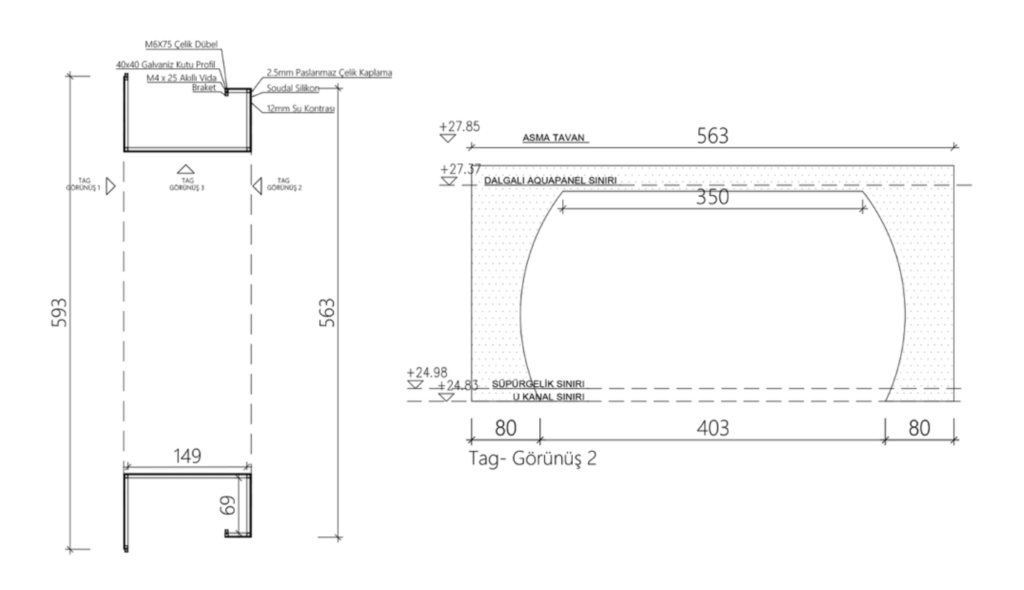

Although there are 12 stainless reduction belts manufactured by Fabrikaco within the Gayrettepe Station, each of these belts presented various differences and unique challenges. In addition to the necessity of solving the technical detail in the most functional way in the field, the precursor criteria included not compromising the expected aesthetics due to the delicate finish of the fine works and not restricting the volumetric parameter due to the tunnel geometry.

Design and Methodology

We cannot pass without mentioning that the equation of the related connection element was one of the extensively considered pens on the table before taking its place on the stage. Because, besides being a challenging geometry, it was an impossible-to-place structure as a whole due to its dimensions and weight. Therefore, it had to be designed as a work that does not compromise aesthetics after being solved in modular pieces like Lego and the visuality of which is preserved.

Workshop Process

When production started in the workshop, the pieces of the modular system supporting each other and completing the design were fulfilling their roles. The main frame forming the supporting system was created from box profiles, and the skeleton of the relevant structure was revealed. While the template created by the supporting structure was supported, the prevention of the inward swing of the coating material that the structure element might encounter over time was ensured by using a water contrast between the supporting structure and the finishing material. After the structure and template were created, the reduction belt achieved an aesthetic perception and made the relevant structural element feel like a symbol in the space with the use of stainless steel.

Application and Architectural Element

The other exciting stage after the completion of the workshop process was the assembly process. The modular system created in the workshop was transported to the metro construction site by being divided into three pieces, and its size and spatial perception were discussed many times. Within the construction site, these modular pieces were welded together to obtain a single connection element. The stainless metal coverings, cut according to a special mold to create the form seen today, were riveted in the construction site, and the structure element called the reduction belt took its place within the station.

In the next content following this series analyzing the process of the reduction belt, we will share with you Fabrikaco’s ceiling manufacturing and unique solutions within the same station structure.